Galvanized Steel Rainwater Collection Cylindrical Round Water storage Tank

Galvanized steel water tanks promote water conservation, can be built on difficult to access sites, can be disassembled, can be relocated, are suitable for active / passive fire protection systems, can reduce well pump strain, can increase property value and are capable of lasting a lifetime.

Round Water storage Tank

Galvanized Steel Rainwater Collection Cylindrical Round Water storage Tank

Galvanized steel water tanks promote water conservation, can be built on difficult to access sites, can be disassembled, can be relocated, are suitable for active / passive fire protection systems, can reduce well pump strain, can increase property value and are capable of lasting a lifetime.

The assembly circular water tank is a structural water tank that is the latest independently developed by our company. It is mainly composed of BDF composite steel plates, self-lock bolts and sealing gums. The main component is stainless steel composite assembly steel plate.

BDF assembled steel plate is made of galvanized steel coil as the substrate, one side with 304/316L stainless steel coil as the panel, through the polymer physical composite, especially suitable for the requirements of modern construction. It has a high degree of standardization such as dividing, opening, punching, and completely processing in the factory. After being packaged and transported to the construction site for assembly. The connection of the steel plate is completely bolted, and we have developed special installation tools to make the installation more simple. The installation process is less affected by weather, and the installation cycle is easy to control.

Installation process:

The splicing between the BDF steel plates adopts the form of overlapping the upper and lower steel plates and connecting with self-locking bolts. The special silicone sealant is embedded between the two plates, and the silicone sealant is rubber after curing, which has the characteristics of high elasticity, high temperature resistance, strong weather resistance and so on. The head of the self-locking bolt is wrapped in plastic and has strong corrosion resistance. The root of the bolt is equipped with four wood devices and has self-locking function. When the tank body is testing water, it can be tightened with water.

Six Main Applications and More

Galvanized steel water tanks are ideal for many applications where a repeat source of reliable water is necessary. Their most common uses are in rainwater harvesting, fire protection, stormwater management, irrigation, agriculture, and potable water sourcing. For rainwater harvesting (RWH), steel water tanks offer the largest volume collection tanks on the market. In fire protection, they frequently service rural precincts, farms or small towns with only a small, maybe volunteer type fire department. For stormwater management, these tanks can help prevent damage or hazards from insufficient infrastructure and help gain control of weather effects over large land ownership cases.

In irrigation uses, our steel tanks serve as welcome alternatives to long draws on well supplies and pumps or from reliance on municipal supply. For agriculture, they help offset dry seasons, unexpected droughts and provide water during growing seasons. In potable water provision, the tanks deliver clean, lasting and certified materials suited for years of drinking water service to businesses, industries, healthcare, educational facilities, storefronts, farms and residences.

Our steel water tanks are also often and suitably used as thermal storage and water cooling tanks as well as brewery and winery tanks.

Applicable Industries: Hotels, Manufacturing Plant, Farms, Home Use, Construction Works , Energy & Mining

Project Case

Q:Do you have your own factory?

A:YES

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 10-15 days if the goods are not in stock, it is according to the quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

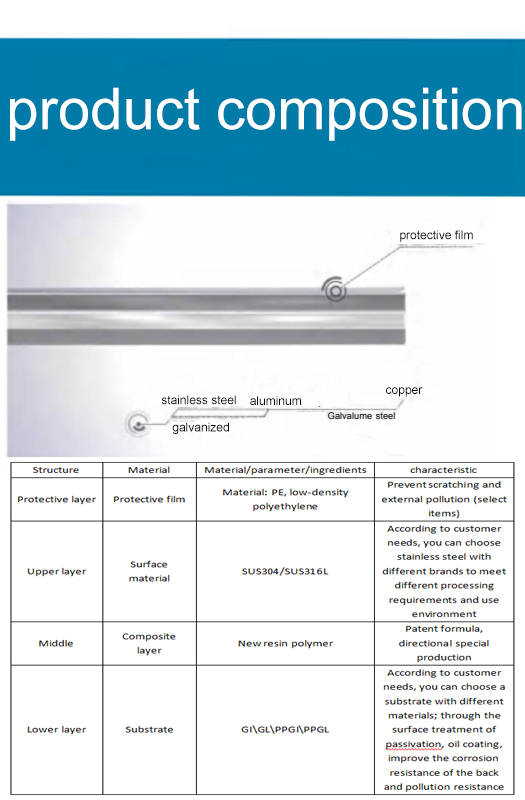

Structure:

|

Structure |

Material |

Material/parameter/ingredients |

characteristic |

|

Protective layer |

Protective film |

Material: PE, low-density polyethylene |

Prevent scratching and external pollution (select items) |

|

Upper layer |

Surface material |

SUS304/SUS316L |

According to customer needs, you can choose stainless steel with different brands to meet different processing requirements and use environment |

|

Middle |

Composite layer |

New resin polymer |

Patent formula, directional special production |

|

Lower layer |

Substrate |

Carbon steel galvanized plate |

According to customer needs, you can choose a substrate with different materials; through the surface treatment of passivation, oil coating, improve the corrosion resistance of the back and pollution resistance |